|

Filling Lines:

We have fillers for both Bottles and Cans.

Bottles

We supply bottling lines for edible oils, sauces, viscous and semi-viscous products. Our filling lines are designed such to accept both glass and PET bottles.

Thanks to the modular engineering design of our machinery, the fillers can be modified to be used for many different packaging types and shapes.

With easy changeover parts, changing your packaging is easier than ever. Our fillers can adjust to the height of the packages. The width and shape changes to the containers can also be accounted for in the line. Thus, in a matter of minutes you can continue your packaging using a different package!

In addition to its ease of use, our fillers are one of the most accurate fillers available.

Our fillers are designed to be filled both cold-fill and hot-fill. Since our filling machines are volumetric fillers, temperature does not effect the filling accuracy. Hence, you get extremely high accuracy on every fill!

Last, but certainly not least, is the capacity. The output capacity of our line differs based on the type of product being filled, viscosity, and container size.

For example, for edible oil, we can reach an admirable capacity (to say the least) of up to 28,000 bottles/hour based on 0.75 L and 1 L glass bottles.

The capacities of our different models vary with one and another but we carry the same precision and quality on all our machines.

Cans

In Iran, Hydrotec is synonymous with canning technology! Our founding managers specialized in metal packaging (i.e. cans) resulting in a famous name for Hydrotec in this ever-changing field.

We have filling lines for viscous, semi-viscous, and even animal & vegetable preserves.

For filling products that are homogenous, we have our rotary volumetric fillers, which fills based on the same principles as our bottle filler, i.e. by volume. As mentioned before, filling by volume is more accurate and temperature independent. Our filling lines vary in capacity from 250 ml â€" 5000 ml cans. Our in-line model fillers are also capable of filling volumes up to 5200 ml.

On the other hand, for filling of particulate mixed canned goods, such as animal and vegetable preserves, a combination of our telescopic filler and vacuum syruper can be used to achieve best quality and accuracy of filling. The vacuum syruper is specially designed for these filling conditions to fill in the exact volume required based on a previous fill of particulate products.

With state of the art technology software to aid it, and excellent workmanship, as with all of our machinery, we can design and engineer practically any filling line that you could possibly need for bottles or cans.

Vacuum syruper

Seamers

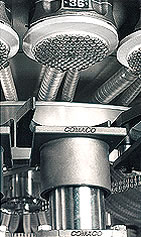

Our seaming machines are the industry standard throughout the world! The AGM series that we offer today is the new and faster version of the same popular AGM series that we first brought into the Iranian industry 20 years ago. With an increase in accuracy and speed and 20 more years of experience added on, our seamers are world-known for quality.

Our automatic high-speed seamers are designed to seal cylindrical metal containers filled with beverages, food, or other products.

Our seamers can range from 3 â€" 12 seaming heads per machine, yielding capacities up to 1,500 cans/minute (depending on various factors)!

Seamer

|